ONGOING PROJECTS

- Development of Remote Radiation Detection Imaging System Mounted on a Drone

- High Resolution SPECT using Variable Pinhole Collimator

- Positioning Algorithm for CZT Virtual Frisch-grid Detector

- Multi-purpose Super-resolution Gamma Detector

- Multi-pinhole SPECT

- Low Profile Light Guide using Diffusion Film

- Advanced Reconstruction for Radiation imaging (ARRA)

COMPLETED PROJECTS

- Reconstruction of Dose Distribution in In-beam PET for Carbon Theraphy

- Image Registration for Breast Cancer Study

- High Energy Collimator Design for I-131

- Plasma-Display-Panel based X-ray Detector (PXD)

- CCD based Gamma Camera

- Abdomen Registration for PET/CT and MR images

- Performance Optimization by Patient Dose Analysis and Image Quality Assessment in CT Fluoroscopy

- Cone-beam based system matrix for a pixelated SPECT detector

- Development of Time-of-Flight Method for Improvement of Signal-to-Noise Ratio

Diffusion Film for the Light Guide of Gamma Ray Imaging System

Introduction

The conventional detector of the nuclear medicine imaging system, such as SPECT or PET, consists of a scintillator and a light detector. It has a light guide between scintillator and light detector to spread the scintillation photons to wider sensing area. With wider diffusion, it is possible to localize the position of gamma ray interaction more accurately. Thus, the spatial resolution of the camera is improved with the light guide. We adopted a thin diffusion film, which is designed for the light diffusion in TFT-LED monitors, for the light guide of gamma ray imaging system. The initial performance of the diffusion film as a light guide has been compared to the conventional acrylic light guide.

Materials and Methods

The gamma ray imaging system is configured with a SiPM based light detector (SensL MatrixSM-9) and 31 x 31 pixelated Ce:GAGG (0.7mm x 0.7mm x 5mm). The reflection material is BaSO₄, and it fills 0.1mm inter-pixel gap. Figure 1 (left) is 2 mm thickness acrylic plate as a conventional light Guide. It was coupled to light detector and scintillator by optical grease (BC630, Saint-Gobain Crystal). For the comparison study, TFT-LED polyester diffusion film (TDF127, Toray), figure 1 (right), was conducted without optical grease. We inserted 0 to 4 sheets of overlapped diffusion films to compare the spreadability of light at each state. The position of each gamma ray interaction has been estimated by Anger logic. Flood-map was obtained and analyzed for each cases and using the Na-22 (511 keV) point. The energy spectrum has been evaluated for each case, as well.

Fig. 1. Light guide. Conventional acrylic board (left) and diffusion film (right).

Results

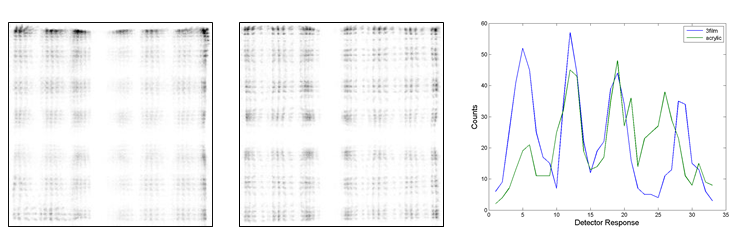

Fig. 2. Result of positioned image of 2 dimension GAGG crystal. Conventional acrylic light guide (left), 3 films light guide (middle) and profile of four crystal pixel of positioned images (right).

The experimental condition of bias voltage, pixel threshold voltage, array threshold voltage, and runtime is 31V, 0.4V, 0.5V, 600 seconds each. The light spreading of acrylic plate and 3 overlapped diffusion films is shown in figure 2. The film case can distinct each dot easily and represent better distinction than acrylic at the edge. The profile of four crystal pixels of figure 2 (left, middle) is shown in figure 2 (right). The film profile is sharp. Moreover, the light loss of the film is much less than acrylic.

Conclusion

In this study, We compare the initial performance of the diffusion film as a light guide to the conventional acrylic light guide. The diffusion film represents excellent properties compared to the acrylic plate, even it is thinner and easier to handle. The diffusion film is an acceptable alternation for the conventional light guides. We can make further research about light guide film according to type of film and use of optical grease.

Participating Researchers